Pulsafeeder

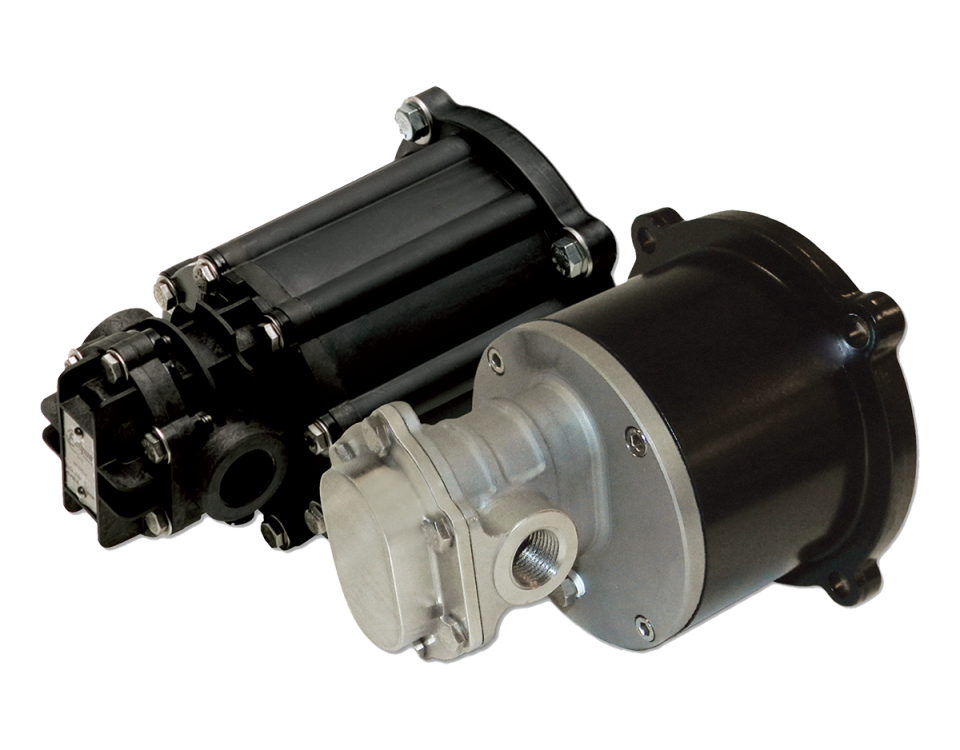

ECLIPSE EXTERNAL GEAR PUMP

Combining proven design principles with patented features, our Sealless gear pumps are safe, simple, and reliable. Structurally rugged with corrosion resistant materials, Eclipse rotary pumps are an ideal fit for many corrosive liquids. From acids to bases, we cover the entire pH scale.

The innovative technology behind Eclipse supports its ability to handle the most corrosive chemicals with a simple-to-service, front pull-out design. Eclipse rotary gear pump, is available with wetted components in completely non-metallic construction and 316SS. These material offerings ensure corrosion resistance over a wide range of chemicals and process conditions. Pulsafeeder Eclipse rotary gear pumps are sealless magnetically driven to eliminate mechanical seal wear and leaks associated with rotating seals. The patented bearing design promotes constant lubrication.

Features and Benefits

Designed for Simplicity

• Fewest number of components of any external gear pump on the market

• Simplified ordering and inventory with fewer parts

• Self-aligning parts and piloted fits ensure proper assembly every time

Renewable Performance

• Patented housing liner protects the housing from wear

• Easy maintenance KOPkit® (Keep On Pumping kit) saves time and money

• Regain like new performance flow with a KOPkit®

Heavy Duty Bearings & Tolerance O-Ring

• Minimal gear and shaft wear with large surface area bearings

• Patented drive shaft spline design optimizes magnet alignment on shaft

• Tolerance O-ring maintains proper internal operating clearances

Magnetically Driven Sealless Design

• Eliminates costly seal flush systems required for double mechanical seals

• Patented drive shaft spline design optimizes magnet alignment on shaft

• Fully encapsulated driven magnets offer maximum corrosion resistance

• Sealless design ensures zero leakage

Universal Flanges

• Standard housings mate to both ANSI and DIN flange connections

• PTFE or Viton® inserts act as a gasket and can be reused or replaced to ensure a proper seal (Non-metallic only)

Universal Motor Adaptor

• Easily couple with many NEMA and IEC motor frame sizes

• Quickly install or retrofit to different motor frame sizes